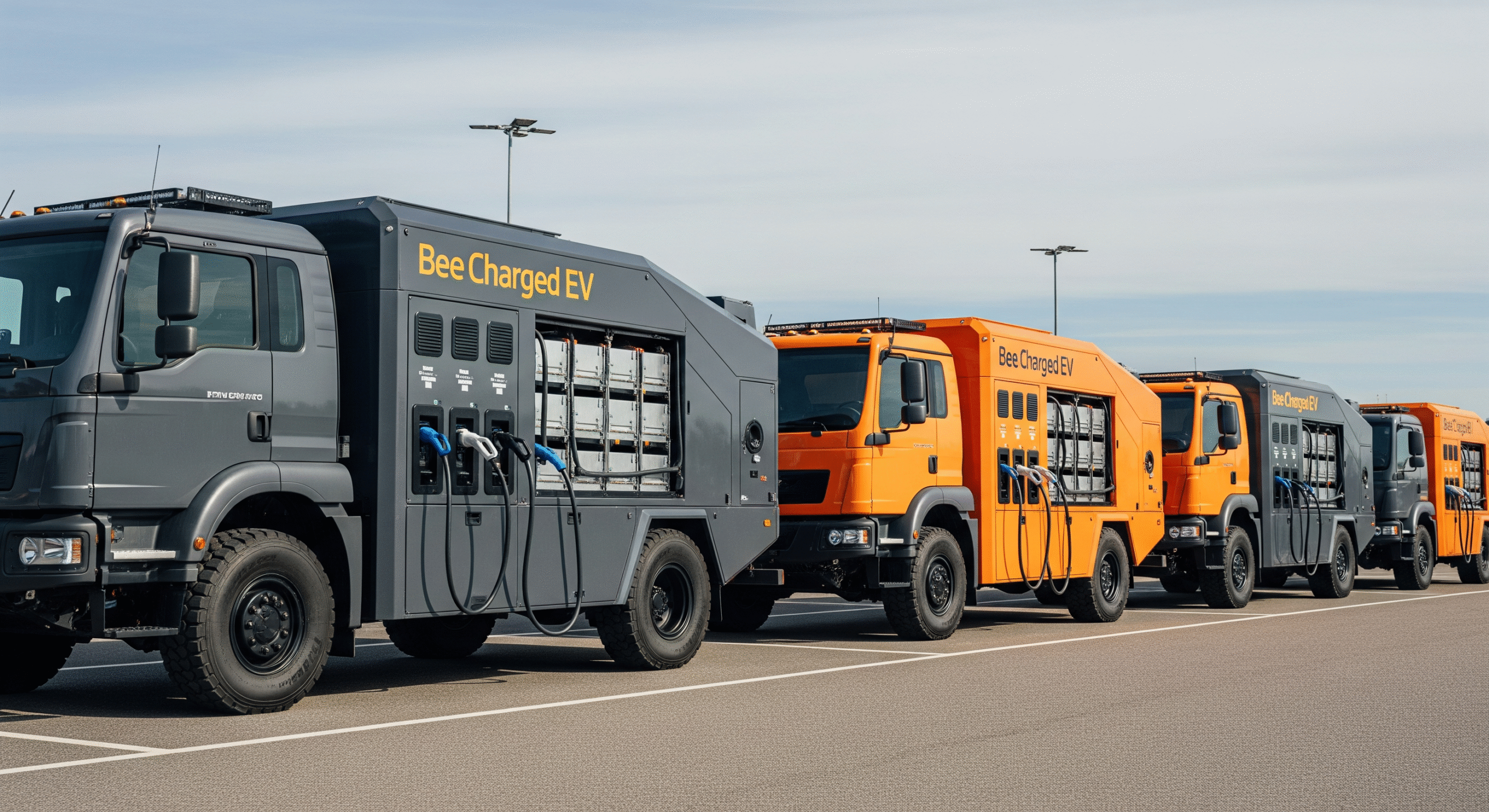

Bee Charged EV Technicians Follow Comprehensive Safety Precautions Including Pre-Service Inspections, Proper Connection Procedures, Active Session Monitoring, Emergency Protocols, and Post-Service Verification

Mobile EV charging technicians from Bee Charged EV implement rigorous safety precautions at every stage of charging service including thorough equipment and vehicle inspections before connection, proper electrical connection procedures, continuous monitoring throughout charging sessions, environmental hazard assessment, emergency response readiness, and complete verification upon service completion. These multi-layered precautions protect customers, vehicles, technicians, and property while ensuring optimal charging results. Our certified technicians undergo extensive training in safety protocols making professional mobile charging significantly safer than self-service public charging stations. Call 888-675-9555 to experience professional mobile charging with comprehensive safety precautions.

Pre-Service Safety Assessment

Before beginning any charging session, technicians conduct thorough assessments:

Site Safety Evaluation:

- Assess charging location for hazards (water, flammable materials, unstable surfaces)

- Verify adequate ventilation especially in enclosed spaces

- Identify potential electrical hazards or environmental concerns

- Ensure safe positioning of mobile charging unit

- Evaluate traffic patterns and pedestrian safety

- Check weather conditions affecting safety procedures

Vehicle Inspection:

- Examine charging port for damage, debris, or corrosion

- Check for visible damage to vehicle electrical components

- Verify charging port door operates properly

- Look for moisture or contamination in charging port

- Inspect vehicle for obvious safety issues

- Confirm vehicle identification matches service order

Equipment Inspection:

- Verify charging cables free of damage or wear

- Check connector pins for damage or contamination

- Test ground fault protection systems

- Confirm all safety systems operational

- Verify equipment calibration and certification current

- Ensure backup safety equipment available

This comprehensive pre-service assessment prevents safety issues before they arise.

Proper Connection Procedures

Technicians follow strict protocols for safe electrical connections:

Step-by-Step Connection Process:

Port Preparation:

- Open charging port door carefully

- Inspect port interior with flashlight

- Remove any debris or contamination gently

- Verify port pins undamaged and properly aligned

Connector Preparation:

- Inspect charging connector thoroughly

- Ensure connector clean and dry

- Verify connector type matches vehicle requirements

- Check locking mechanism functionality

Initial Connection:

- Align connector carefully with port

- Insert connector smoothly without forcing

- Ensure proper seating and alignment

- Verify mechanical locking engagement

Electrical Verification:

- Confirm vehicle-charger communication established

- Verify charging handshake successful

- Check indicator lights show proper status

- Monitor initial power delivery startup

Safety Confirmation:

- Double-check connection security

- Verify no unusual sounds, smells, or heat

- Confirm all safety systems active

- Document connection completion time

Never Force Connections:

Technicians never force connectors—resistance indicates misalignment or damage requiring assessment before proceeding.

Proper Hand Positioning:

Trained hand positions ensure safe grip preventing hand placement near electrical contacts.

Weather Adaptations:

Special procedures for rain, extreme heat, or other conditions affecting connection safety.

Active Charging Session Monitoring

Unlike unattended public charging, technicians actively monitor sessions:

Continuous Observation:

- Technician remains on-site or nearby during charging

- Regular visual inspection of connections and equipment

- Monitoring of charging equipment displays and indicators

- Attention to any unusual sounds, smells, or observations

- Vehicle instrument panel monitoring when visible

Temperature Monitoring:

- Periodic touch-test of connector and cable for excessive heat

- Infrared temperature monitoring for longer sessions

- Battery temperature tracking through vehicle systems

- Ambient temperature consideration for charging management

Electrical Monitoring:

- Verify consistent power delivery throughout session

- Monitor voltage and current levels for abnormalities

- Check for fluctuations indicating potential problems

- Confirm vehicle-charger communication remains stable

Environmental Monitoring:

- Watch for changing weather conditions

- Monitor for new hazards entering charging area

- Ensure charging location remains safe throughout session

- Address any environmental changes affecting safety

Customer Communication:

- Provide charging progress updates

- Answer customer questions about process

- Explain observations or recommendations

- Coordinate completion timing with customer needs

This active monitoring enables immediate response to any issues.

Emergency Response Preparedness

Technicians maintain readiness for unlikely emergency situations:

Emergency Equipment:

- Appropriate fire extinguishers (Class C electrical)

- First aid kits in all service vehicles

- Emergency contact information readily available

- Personal protective equipment available

- Emergency shutoff procedures practiced

Emergency Procedures:

- Immediate power disconnection protocols

- Vehicle fire response procedures (specific to EVs)

- Customer evacuation guidance if needed

- Emergency services contact procedures

- Incident documentation requirements

Training and Drills:

- Regular emergency response training

- Scenario-based practice exercises

- Annual recertification in emergency procedures

- Knowledge of local emergency services

- Coordination with fire departments and first responders

Incident Response:

- Immediate assessment of situation severity

- Customer safety prioritization

- Proper emergency service contact

- Scene control and hazard mitigation

- Detailed incident documentation

While emergencies are extremely rare with professional mobile charging, preparedness ensures optimal response if needed.

Battery Health Protection Precautions

Technicians take precautions protecting long-term battery health:

Temperature-Aware Charging:

- Assess battery temperature before charging

- Adjust charging rates for extreme temperatures

- Recommend optimal charging timing in Los Angeles heat

- Allow hot batteries to cool before fast charging

- Monitor temperature throughout session

Charging Rate Management:

- Select appropriate charging speed for situation

- Balance speed needs with battery health

- Follow manufacturer recommendations for charging rates

- Avoid excessive fast charging when unnecessary

- Optimize charging curves for battery longevity

State of Charge Considerations:

- Recommend optimal charge levels (typically 20-80%)

- Avoid regular charging to 100% unless needed

- Prevent deep discharge situations

- Balance immediate needs with long-term health

Charge Cycle Optimization:

- Educate customers on healthy charging practices

- Recommend charging frequency and patterns

- Identify potentially harmful charging habits

- Provide battery health maintenance guidance

Our mobile EV infrastructure prioritizes battery longevity alongside immediate charging needs.

Electrical Safety Protocols

Comprehensive electrical safety procedures protect everyone:

Personal Protective Equipment:

- Insulated gloves when appropriate

- Non-conductive footwear

- Safety glasses for outdoor work

- High-visibility clothing for roadside service

Lockout/Tagout Procedures:

- Proper isolation of electrical systems when servicing equipment

- Clear marking of equipment status

- Coordination between technicians on multi-unit operations

Arc Flash Protection:

- Awareness of arc flash hazards

- Proper approach distances

- Use of arc-rated equipment when appropriate

- Training in arc flash response

Ground Fault Protection:

- Verification of proper equipment grounding

- Testing of ground fault protection systems

- Immediate response to ground fault indicators

- Understanding of grounding requirements for various surfaces

Wet Conditions Procedures:

- Enhanced precautions during rain

- Verification of moisture protection

- Additional inspection of electrical connections

- Appropriate timing of service in wet conditions

Customer and Property Protection

Precautions extend beyond vehicle safety to customers and property:

Customer Safety:

- Clear communication about process and safety

- Instructions for customer actions during charging

- Guidance on safe distances from equipment

- Explanation of what to do if problems occur

- Respect for customer comfort and concerns

Property Protection:

- Careful positioning of mobile charging units

- Protection of driveways, lawns, and landscaping

- Avoid blocking access or creating hazards

- Clean up any materials or debris after service

- Respect for private property and facilities

Vehicle Exterior Protection:

- Careful handling of charging port doors

- Avoid contact with vehicle paint or surfaces

- Proper cable routing preventing damage

- Gentle treatment of all vehicle components

Neighbor Consideration:

- Minimize noise and disruption

- Proper parking of service vehicles

- Professional conduct and appearance

- Respect for community standards

Documentation and Verification

Thorough documentation supports safety and quality:

Pre-Service Documentation:

- Vehicle identification and specifications

- Initial battery state of charge

- Visual condition observations

- Customer service requests and requirements

During-Service Documentation:

- Charging parameters (voltage, current, power)

- Temperature readings at intervals

- Any unusual observations or events

- Communication with customer

Post-Service Documentation:

- Final state of charge achieved

- Total energy delivered

- Service duration and completion time

- Equipment performance notes

- Customer acknowledgment of service completion

Digital Records:

- Photographic documentation when appropriate

- Electronic service records in central system

- Maintenance of service history

- Warranty and compliance documentation

This documentation provides accountability and supports quality assurance.

Disconnection and Completion Procedures

Safe service completion is as important as connection:

Charging Completion:

- Allow proper charging termination by vehicle systems

- Verify charging fully stopped before disconnection

- Check final status on vehicle and charger displays

- Confirm customer satisfaction with charge level achieved

Disconnection Procedure:

- Unlock connector using proper technique

- Remove connector smoothly without force

- Inspect connector immediately after removal

- Check vehicle port for any issues

- Close charging port door securely

Final Inspection:

- Verify vehicle charging port area looks normal

- Ensure no tools or materials left behind

- Check no damage occurred during service

- Confirm charging location returned to original condition

Customer Handoff:

- Provide service summary to customer

- Answer any final questions

- Offer recommendations or guidance

- Confirm customer satisfaction

- Provide receipt and documentation

Continuous Safety Improvement

Bee Charged EV maintains ongoing safety enhancement:

Incident Analysis:

- Review of any safety issues or near-misses

- Root cause analysis of problems

- Identification of prevention measures

- Implementation of corrective actions

Technician Feedback:

- Regular safety meetings with technicians

- Sharing of observations and concerns

- Collaborative safety improvement

- Recognition of excellent safety practices

Technology Updates:

- Adoption of new safety technologies

- Equipment upgrades enhancing safety

- Monitoring of industry safety developments

- Integration of best practices

Customer Feedback:

- Attention to customer safety concerns

- Response to observations or suggestions

- Continuous improvement based on experience

- Transparency about safety practices

Regulatory Compliance

All precautions align with regulatory requirements:

OSHA Compliance:

- Workplace safety standards adherence

- Proper training documentation

- Hazard communication program

- Injury and illness prevention program

Cal/OSHA Requirements:

- California-specific safety regulations

- Heat illness prevention (important in LA)

- State safety training requirements

Electrical Code Compliance:

- National Electrical Code adherence

- California electrical safety standards

- Industry-specific electrical requirements

Vehicle Manufacturer Requirements:

- Following OEM charging specifications

- Compliance with warranty requirements

- Adherence to manufacturer safety guidelines

Quality Assurance and Oversight

Multiple layers ensure consistent safety precautions:

Supervision and Mentoring:

- New technicians work under supervision initially

- Ongoing mentoring and guidance

- Regular performance evaluation

- Safety compliance monitoring

Random Quality Checks:

- Unannounced service observations

- Review of documentation and procedures

- Equipment inspection and testing

- Customer feedback review

Certification Maintenance:

- Annual recertification requirements

- Continuing education mandates

- Skills testing and verification

- Safety training updates

Management Oversight:

- Regular safety performance review

- Investigation of any issues

- Resource allocation for safety priorities

- Leadership commitment to safety culture

As the most knowledgeable mobile EV charging company with experience across all 50 states and over 1,500 members nationwide, Bee Charged EV has refined safety precautions to industry-leading standards.

Experience professional mobile charging with comprehensive safety precautions. Call 888-675-9555 or visit beechargedev.com for the safest mobile EV charging service in Los Angeles.